We did hesitate for a while ... are we going for coppercoat or not? For those who don't know what that is ... coppercoat is an underwater paint that consists of an epoxy resin supplemented with a good amount of copper powder. Hence the name. The advantages of coppercoat is that the underwater ship is maintenance-free for the next 10-15 years except for a light annual sanding (which can also be done underwater). This is because this epoxy dissolves much less quickly than standard antifouling. This will make us much more independent of finding a good place to get out of the water for an annual or at least bi-annual antifouling over the next few years during our voyage. It is also more environmentally friendly because much less paint disappears into the water. But it's an investment and it's a big job to apply, and it's not without risk. There are plenty of horror stories on the Internet where the coppercoat is not applied properly and fouling occurs. Then you are even further from home.

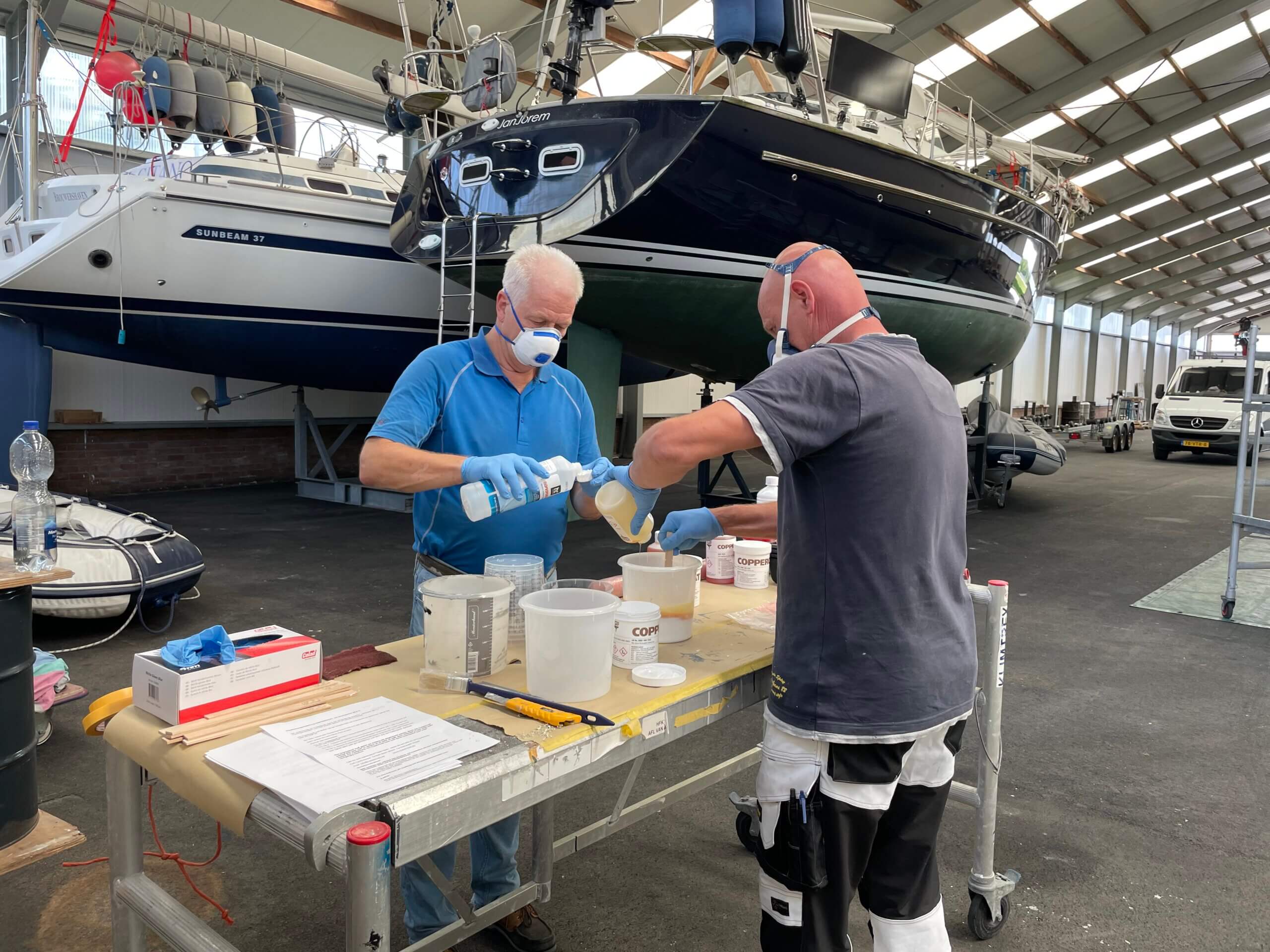

Toine scours the Internet and watches many youtube videos. He would like to understand for himself exactly what the success factors are and, for the most part, wants to do it himself. "It mainly goes wrong if the coppercoat is not applied at the right pace with proper mixing of the paint components in too hot or cold temperatures. Sufficient sanding of the applied layers is also very important," said Toine. With the help of Henri the painter, he dares.

The toughest job is the complete stripping of the underwater hull. Toine starts this himself and fortunately after a week of hard work he gets help from a couple of strong men from CCA who finish the job, including sanding. The SeaQuest is now in the hall because the mast had to be removed anyway to replace the stay. That's a good thing because applying the coppercoat requires four dry days in a row and there are none in this changeable summer. Wet coppercoat reacts with water and with rain it drips right off 🥲.

Once that's done, the construction can start. That's the fun part. Toine, together with Henri, applies two coats of primer. The first layer is gray and the second layer is light yellow. To apply the six coats of coppercoat, the whole family is called in 😎. This is because it is important to do it at a brisk pace and apply the next coat in time before the previous coat becomes too dry. "Wet on wet painting" according to Toine. That's why 3-4 dyers are needed.

We have a nice division of labor. Henri continuously mixes a little paint, distributes it in our bins and walks around himself with the brush for the parts we can't reach with the rollers. Eline and I roll one side together, and Toine and Marinthe the other side. We work from back to front, the girls on the scaffolding with wheels the high part and Toine and I the low part.

The first coat still doesn't cover at all. We knew that in advance. Only the third layer covers somewhat but the fourth and fifth layers are the most "satisfying" to do 😊. The sixth layer is biting through because then we are tired. After 5 hours of hard work, we are done. We did it!!!!! For Toine a huge relief to have come this far after all the hard work. Also very nice to be able to do this together as a family 😊☺️.

After three days of hardening, the coppercoat must be sanded to bring the copper particles to the surface instead of the shiny epoxy. It takes some searching with which grit number sandpaper and how much to sand off. Finally, Toine sanded it with the 320-grit 320-grit sander in two directions. After 'bucking' the 4 small areas where the uprights have been, they also have to go through the whole procedure of stripping bare, 2 layers of primer and 6 layers of coppercoat. Toine does that in two days along with sanding. Just before launching, Van Ast paints the underside of the keel with a lick of good paint. And the whole operation is finished.

In the water, the color will gradually change from copper brown to gray/green due to oxidation over the next few weeks. We are enormously pleased with the result. Besides no to little maintenance, it has only made the boat more solid with all those layers of epoxy.